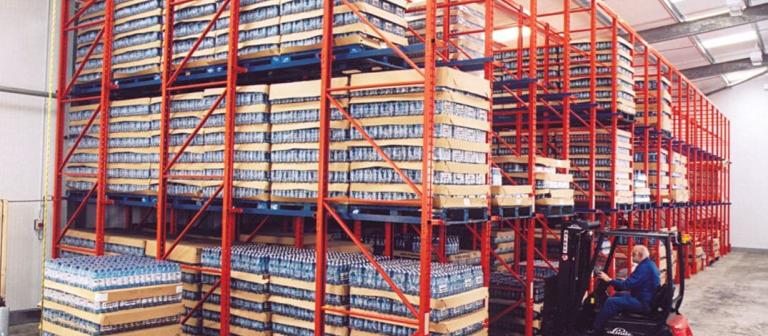

Drive In pallet Racking has a compact design providing high-density storage.

Drive In pallet racking is produced by a number of different manufacturers and each uses its own very specific design. Manufacturers such as Link 51, Dexion, and Mecalux, to name just a few produce their own components specifically for their own system. The main components used in the systems such as uprights, bracing or baseplates are generally the same components used within their other racking systems, they're just reconfigured for this very specific storage type.

Drive In pallet racking was developed as an alternative to block stacking, a system where one pallet is placed one on top of the other. Block stacking was and still is a way to squeeze as many pallets into an area as possible when the space available is limited. In block-stacking, pallets are placed on the floor and pushed up against each other in rows and also stacked vertically, layer upon layer. This method has some obvious drawbacks including damage to goods and a very limited pallet selection.

Block stacking is still used but reserved for low-cost items or raw materials where damage is more likely. Palletised flat-packed cardboard boxes are an example of low value, lightweight items which can be block stacked, sheet materials are another example. Block stacking doesn’t require an initial investment or special equipment so is an obvious choice in some environments.

Drive In pallet racking offers a way to retain the high density of storage usually associated with block stacking but it also improves pallet selection and allows better use of the available building height. Pallet selection is still limited when compared to APR or Narrow Aisle racking but it offers a great solution for certain applications.

Drive In Racking Configuration

Because Drive In pallet racking is designed as a standalone block, modifications to the system are not usually an option. Its structure is calculated based on fixed pallet quantities, pallet weight and handling equipment. Modifications to the system would potentially compromise its structural safety. If the same software program from the original manufacturer were to be used then it is possible to increase the width of the block by adding more lanes. Increasing the block height or depth is not possible and it must retain its original configuration.

Drive in pallet racking is configured in a way that creates a series of lanes for the storage of the pallets. Each lane has levels constructed from rails that run the depth of the lanes. Rails are in pairs and form a type of track for the pallets to sit on. When a level is selected for which a pallet is to be stored, the pallet is lifted above that level and the forklift drives into the lane and deposits the pallet at the rear of the system. The forklift then reverses out leaving the pallet in place. This procedure is repeated until the system is filled to capacity.

There is a sequence that needs to be followed when depositing or retrieving pallets from within a drive in pallet racking system. The first pallet to be stored is placed on the ground at the back of the chosen lane. The spaces above the first pallet are then filled with each rail level above being utilised. Once all rail levels are holding a pallet towards the back of the system then the next floor position is used. This stacking process moves forward pallet by pallet until the lane is full.

Drive In Racking Features

Because pallets are stored in lanes one behind the other it limits access to the pallets buried furthest in the system. This type of system is referred to as a First in Last Out or FILO type operation. Because not all pallets are immediately accessible, drive-in systems are best used for storing a single SKU or product type per lane. Reserving each lane in this manner, reduces pallet handling and ensures the required pallet can be reached.

As well as pallet rails the system can also utilise a guide rail system. Guide rails are floor mounted and serve a different purpose to the pallet rails. Guide rails are used to help prevent the forklift truck from colliding with the racking as it manoeuvres into each lane. The guide rail creates a physical barrier between it and the racking structure. Guide rails also serve to help ensure the truck is central in the lane as it moves forwards during the operation and can facilitate a quicker and more efficient pallet handling procedure. Guide rails vary in their design and can be manufactured from RSA, RHS or channel sections, each manufacturer has its own preferred method.

Caution must be taken when accessing a lane driving a forklift truck, this is to help prevent the truck or pallet from colliding with the racking system. To help minimise the damage from accidental contact, two types of protection can be used. The pallet rails can be equipt with a lead-in attachment which converts the flat end of the rail into a smooth chamfered ‘nose’ which is much more forgiving if a pallet should make contact. The guide rails are also fitted with a rounded lead-in, this performs the same function but allows the truck to transition easier into the aisle. The Front frames of the systems can have column protectors bolted to the lower portion of the upright, this adds an extra guard in case of careless driving.

Drive In Racking Use

Drive in racking lends itself for use in cold stores and refrigeration settings. Storage space within a cold store is usually at a premium so high density is beneficial. It is also a perfect solution when a large quantity of the same product is to be shipped together. Being able to retrieve a full lane all at once ready for delivery means that the limited selection associated with drive-in pallet racking is no longer an issue.

Up to 85% of a warehouse can be utilised with drive in pallet racking while still being perfectly operational. Drive in pallet racking doesn’t allow for the selection of individual pallets but if you are moving lots of the same product all at once then a drive-in racking system could be a perfect choice. The system is ideal for use with either a counterbalance or reach truck. Lane widths can be adjusted to suit almost any pallet size however each pallet must be in good condition.